Polyurethane is a very versatile material that is used in so many products it would be nearly impossible to list, from surface finishes to insulation to furniture making it is all around us.

We make up polyurethane belts in our workshop for machines that may have hard to find or odd size belts, and in other cases will use them due to their excellent performance. They can be run at lower tensions while still delivering excellent traction, which helps machines and motors run more efficiently.

This type of belt is designed to be cut and fused together at a temperature of 275C to 295C at which point it softens, and the cut ends can be pressed / welded together. One should never heat this material beyond that, as just like burning other plastics it has the potential to release potentially dangerous fumes. PU belting is formulated to be heat resistant, and the type of polyurethane used is also safer that that which is used in things like spray foams. Since it is also extremely dense and the working area is so small, it has a much higher ignition temperature… it does not burn very easily.

Belt welding kits are widely available with the most basic being an electrically controlled heated plate, while others have clamps, pressers, and guides much like pliers but those are quite expensive and are generally used in commercial applications.

One should observe the same cautions as they do when they are spraying with products that contain polyurethane, as aerosols have the most potential to cause issues. Proper ventilation and a mask are advised and as the material gets quite hot at the contact points, one should take care not to burn themselves.

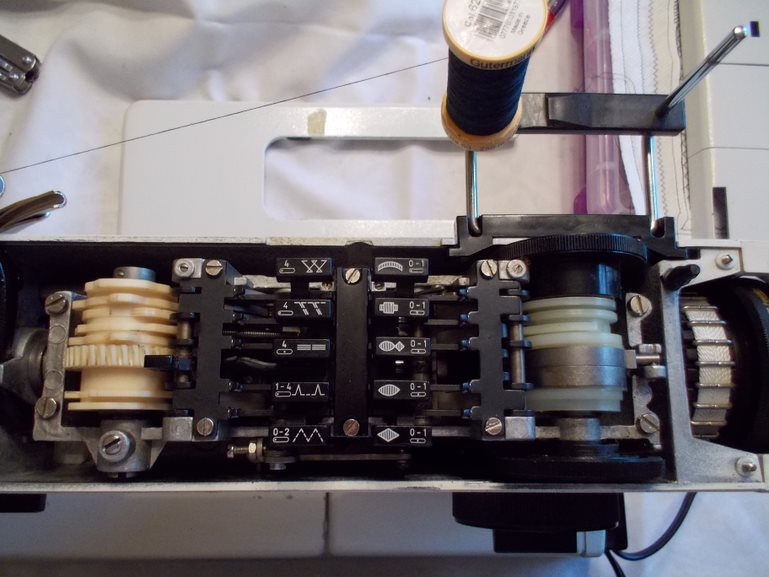

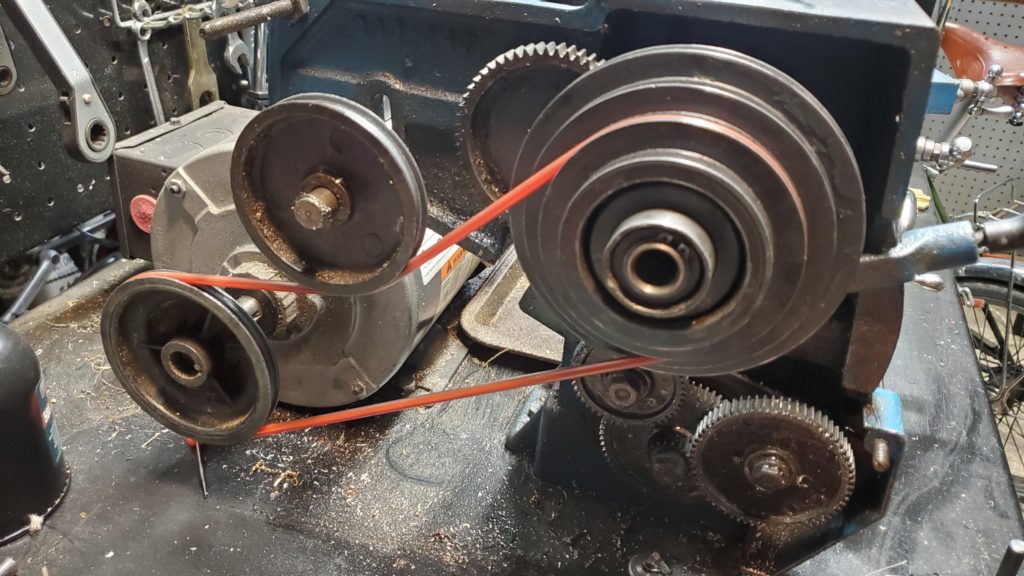

On it’s own PU belt is chemically inert, extremely tough, slightly flexible, and resists oil and solvents, I run the same orange belting you see on my Bernina 125 on industrial machines, and on my 1/2 hp lathe which has been there for years.

Most people who run smaller lathes like mine use polyurethane belts as they are superior to the original V belts and last longer.

The belt on my wee Bernina may last forever… happy sewing.