When you have a little shop that makes parts for sewing machines, accuracy is important, and as I have yet to install a DRO (digital read out) on my lathe I have no way to measure carriage travel save for measurements on the parts.

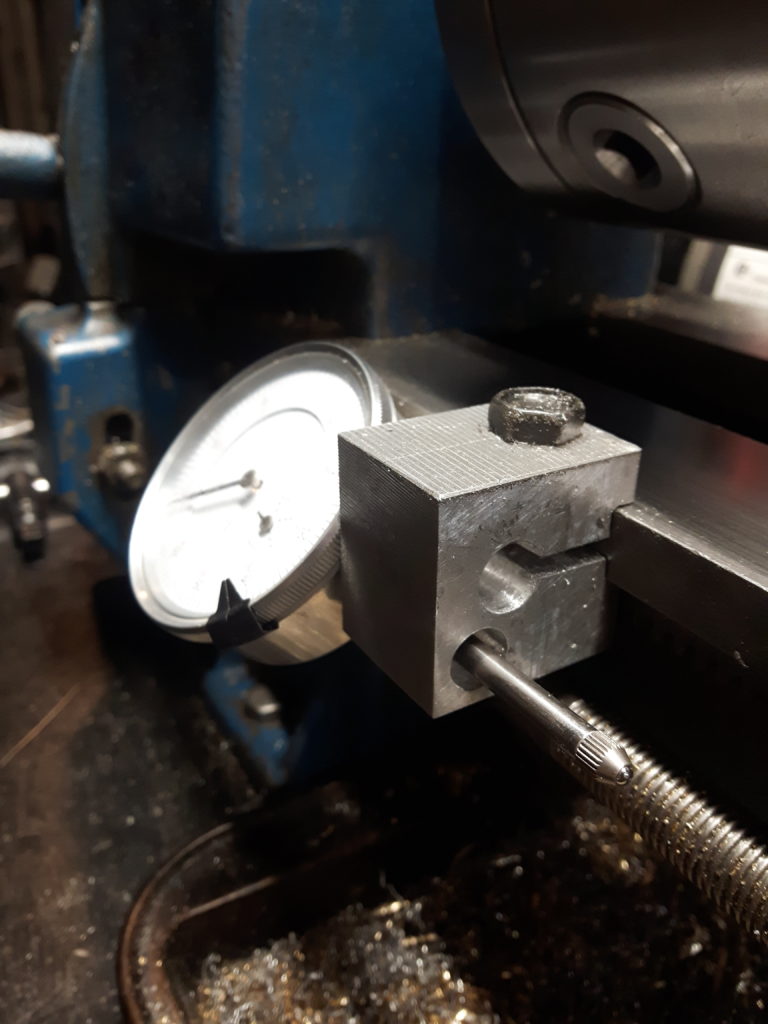

In not too much time I made this carriage stop with a mount for a dial indicator, test fitting it here before I drilled and tapped a few small holes for set screws.

All finished up with set screws to hold the indicator and a proper washer under the nut to keep the bolt from biting into the aluminium. This is for taking accurate depth measurements when I am facing parts, or needing accurate measurements on small parts.

The block also accepts a sliding rod I machined to use as a moveable stop, increments on the rod are marked at 1/10 of an inch to give me a simple reference.

My daughter, who has only taken a passing interest in the lathe saw this and said that it was really cool and asked “you made that ?”.

Will have to spend some time with her showing how it all works as the kid does have some mad skills and likes math, which is rather essential for making parts.

Back to your regularly scheduled sewing content… I did make a new tree skirt from some vintage fabric we thrifted the other day.